Profile

Since its establishment

Wuhan Chidian Technology Co., Ltd. has always regarded product quality as the core competition of the company in market. It is precisely because of product positioning and the strong product quality awareness of all employees that the company continues to develop and is getting better and better.

In the auto parts industry, there are two key factors of product quality control, one is raw materials of the components, and the other is the process control of the production.

First, in the purchasing of raw materials, high quality is the only choice for our production.

1. Thick Film Resistors: All high-precision, high wear-resistant ceramic resistance.

2. Spring: Imported spring steel.

3. The alarm board developed by our chief engineer that is exclusively owned by our company.

4. Media separator: all fold resistant, high temperature resistance, anti-aging, made of corrosion and other excellent properties of rubber and high-strength fabric and other polymer materials.

Second, the product debugging and testing equipment is independently researched and developed by the company. It has uniqueness and leading technology to automate the testing process and intelligently judge the testing results.

Third, in the quality control process, every product will be tested three times before delivery.

Stage I: preliminary adjustment of the product. Which includes two aspects:

1. To debug the resistance value of the detection points

2. To test reliability of detection point for the entire process from zero to the full scale pressure. Prevents the occurrence of momentary short-circuit between two detection points due to dust, fibers, other impurities on the circuit board or poor manufacturing of the circuit board, mainly due to the sudden abnormal occurrence of the meter pointer.

Stage II Semi-final product testing include 4 aspects:

1. To test the resistance value of the detection points

2. To test reliability of detection point for the entire process from zero to full scale pressure

3. To debug and test the pressure value of the alarm

4. To test reliability of detection for the entire process from zero to alarm value.

Stage III Final product testing include four aspects:

1. To test the resistance value of the detection points

2. To test reliability of detection point for the entire process from zero to full scale pressure

3. To test pressure value of alarm

4. To test reliability of detection for the entire process from zero to alarm value.

Regardless of the size of the company, whether the funds are strong or not, the quality control of the product is life of the company and our responsibility. We are confident that we will not produce an unqualified product and will not allow an unqualified product to out of factory.

Yours satisfaction is the motivation of all of us!

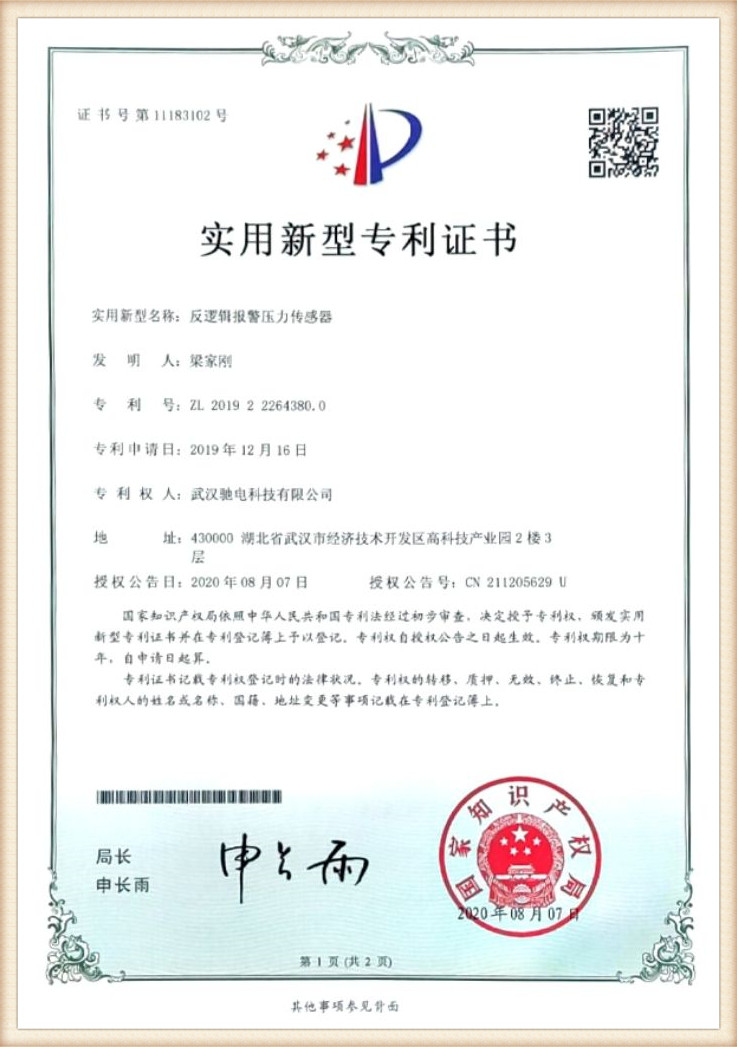

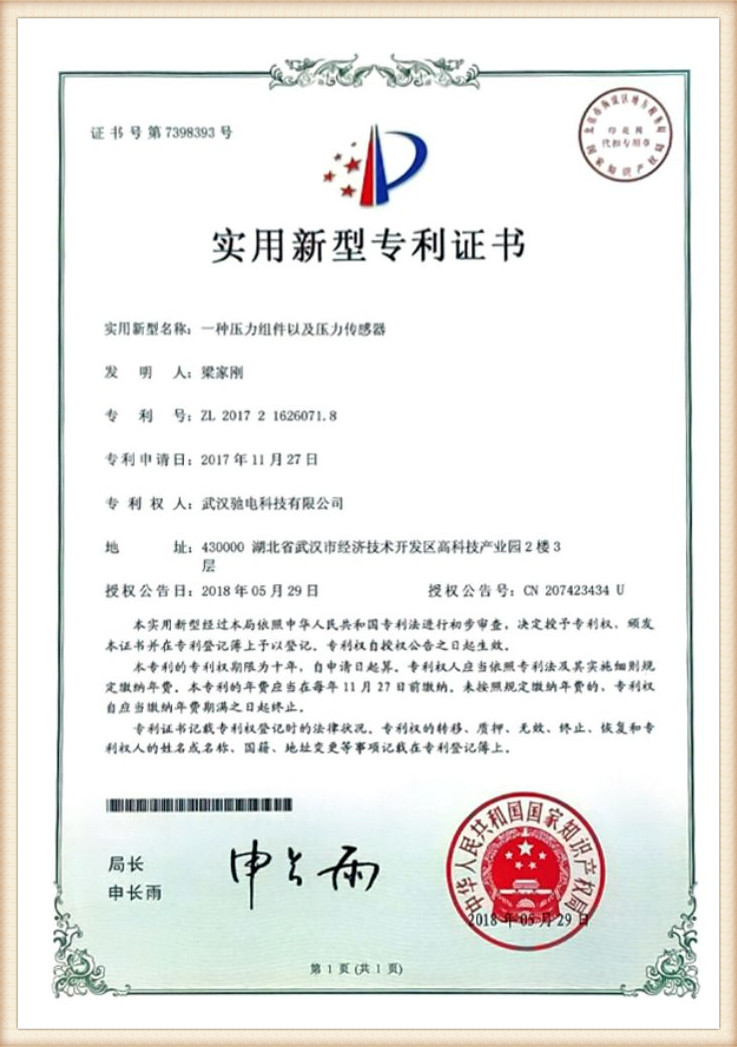

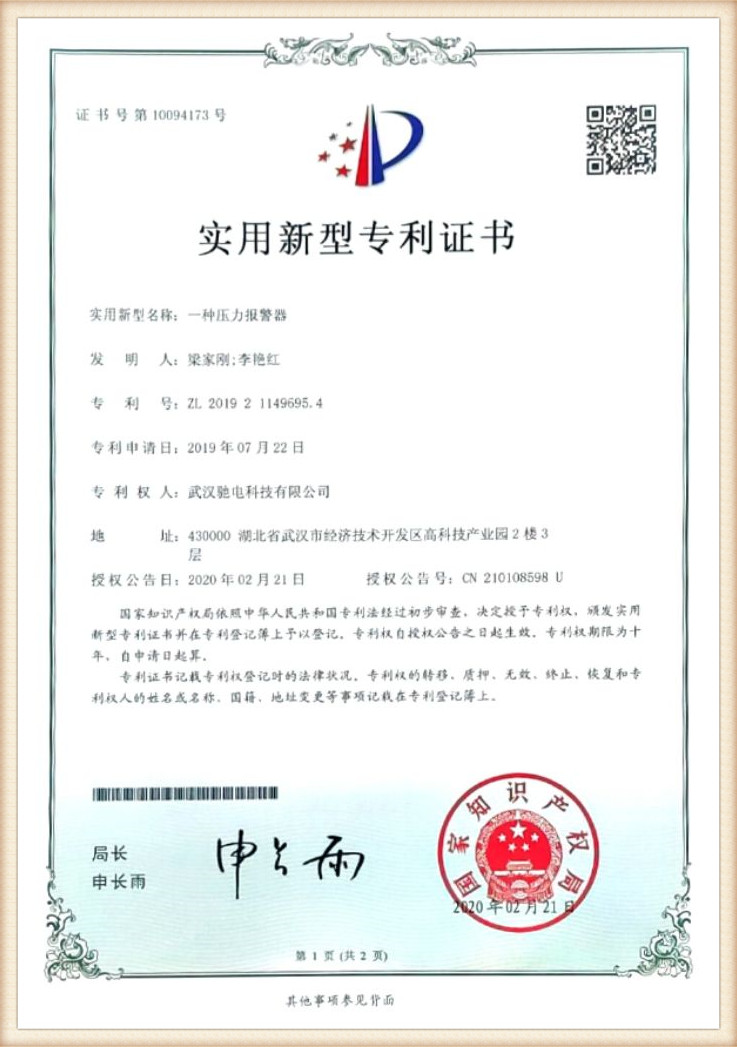

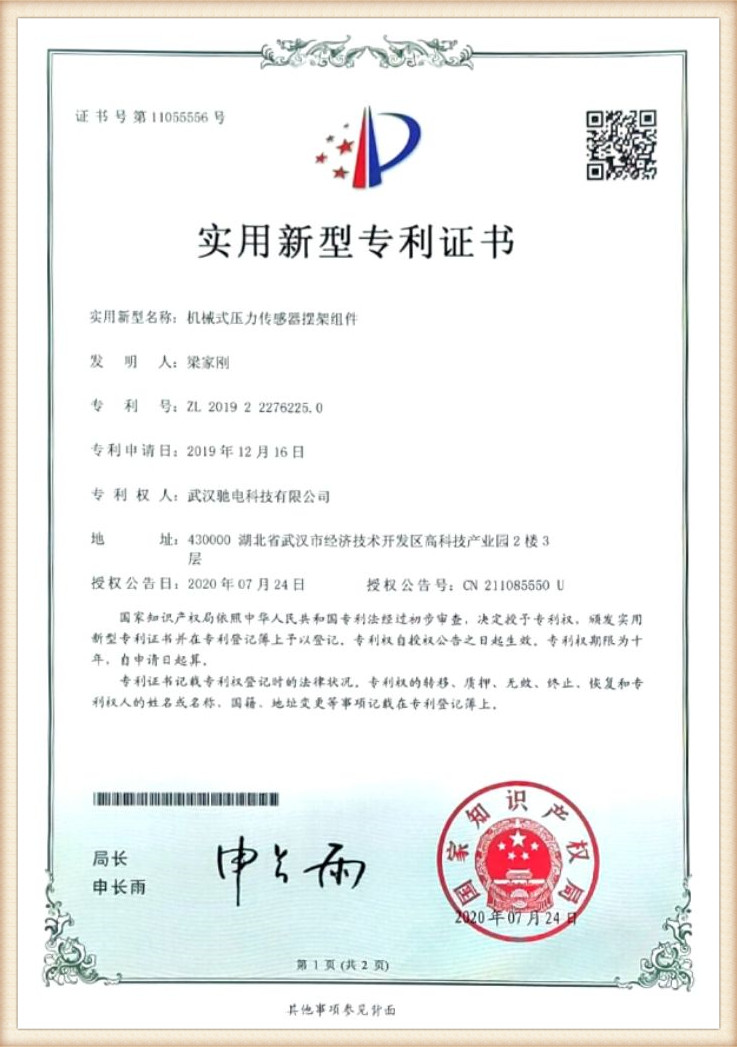

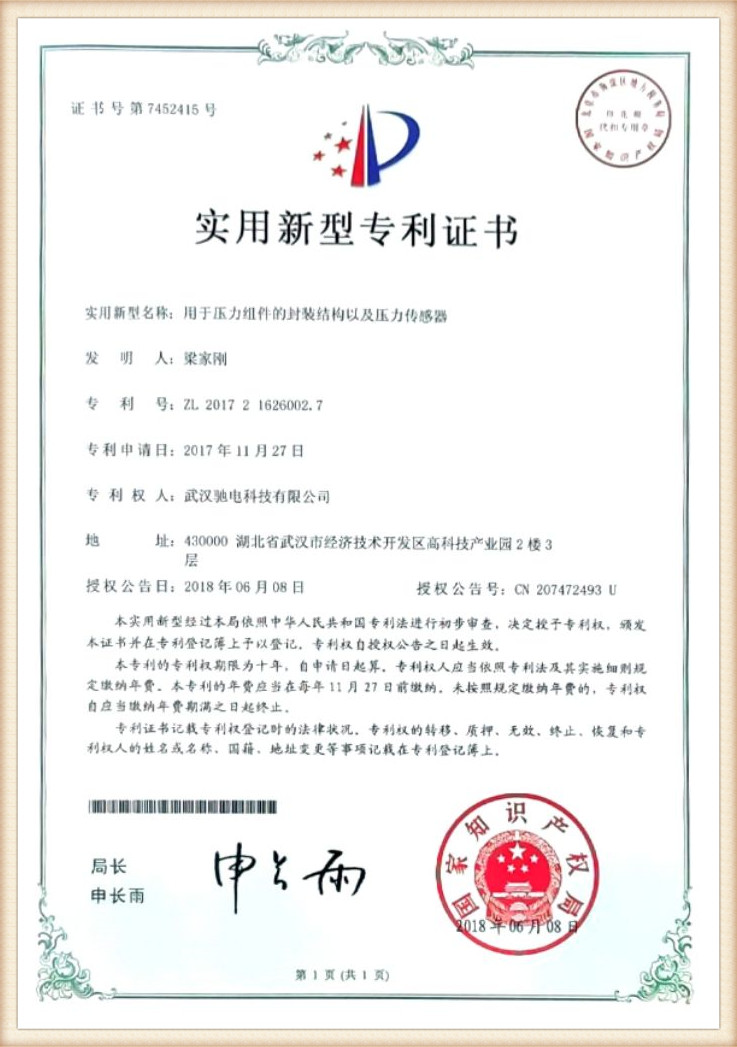

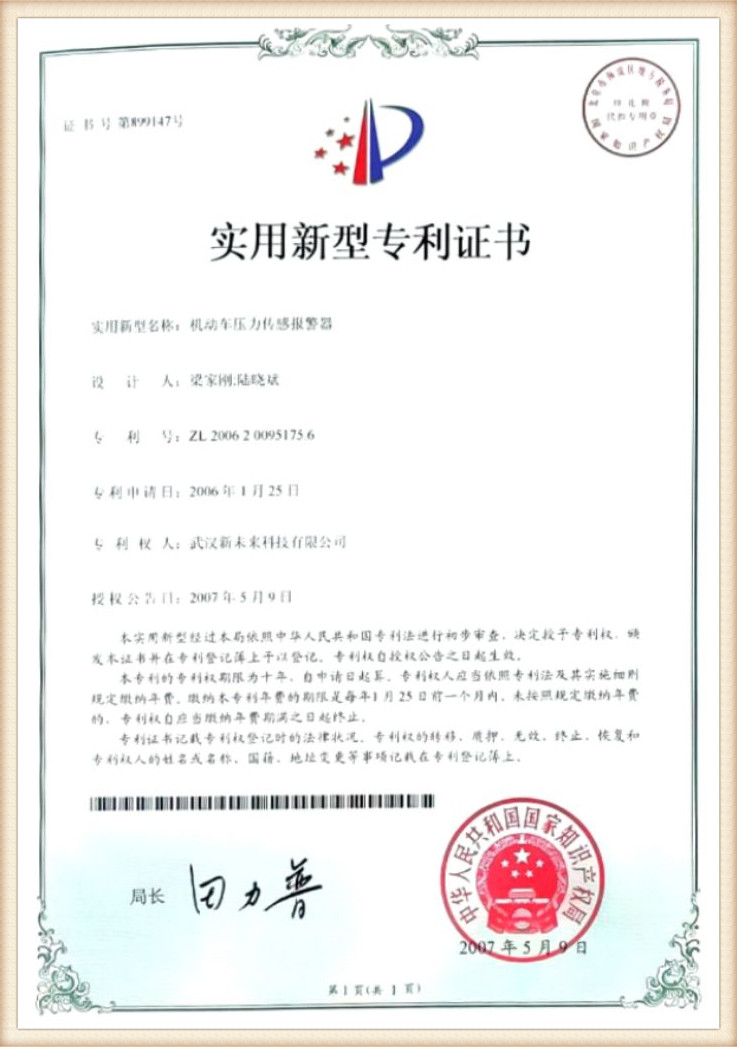

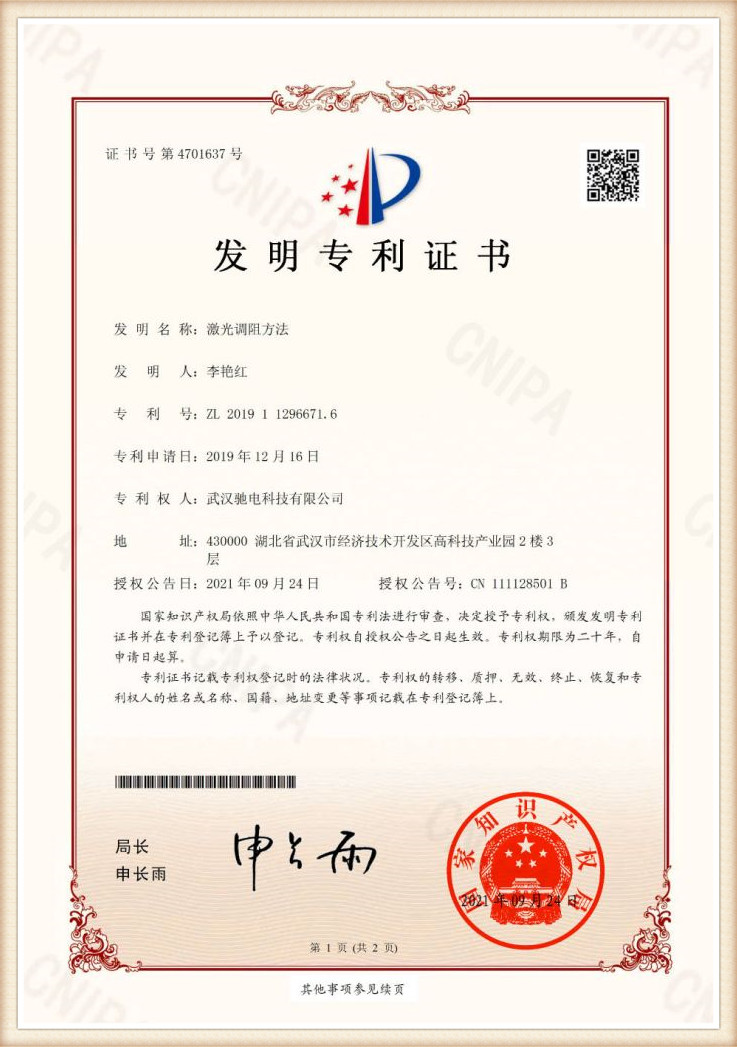

Certification

Standard: RoHS Test Report

Number: BMC3QETH40536704

Issue Date: 2018-04-19